How to Use Correctly Heat Gun for Circuit Board?

AzaelLiShare

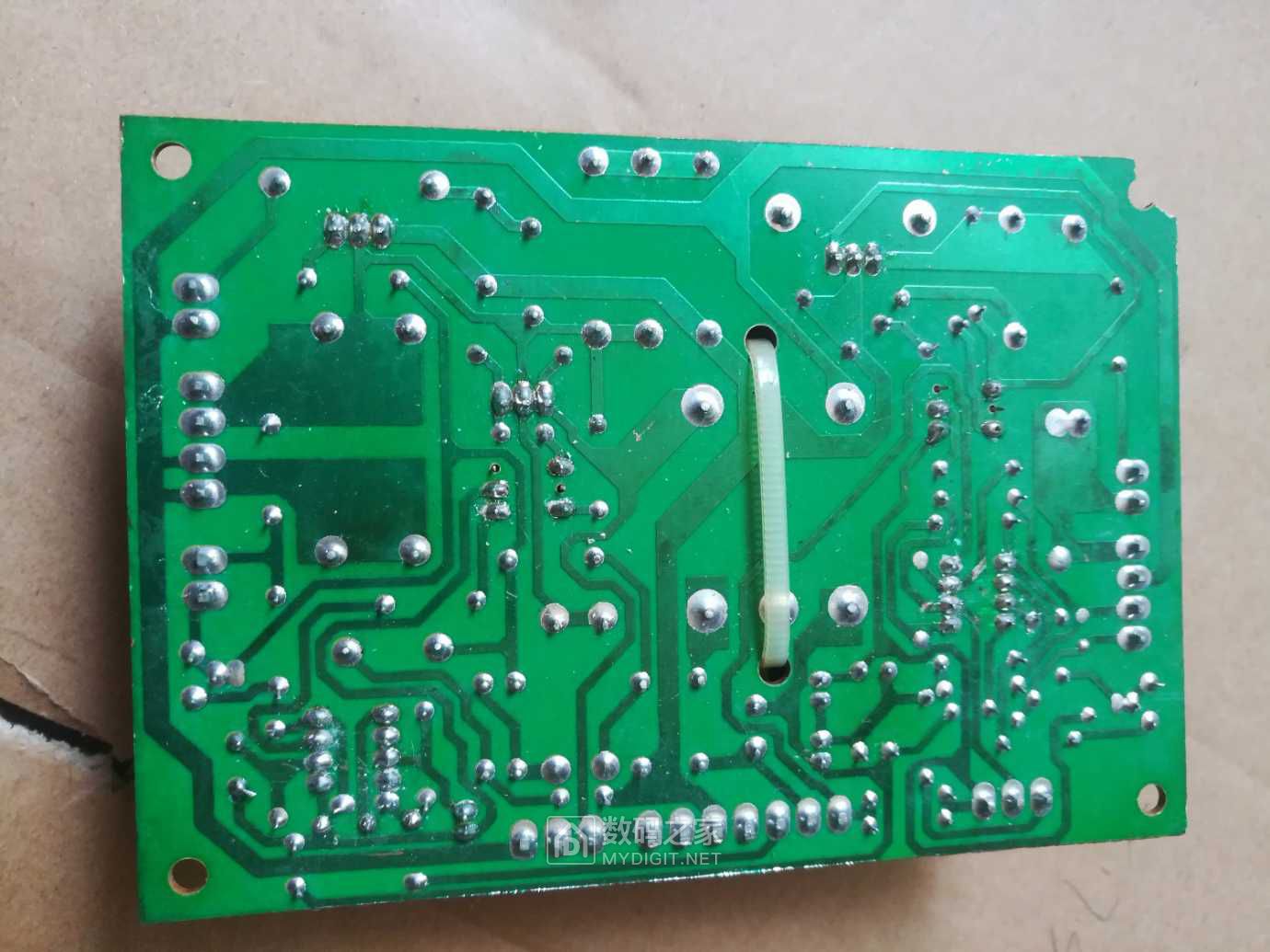

Blow soldering new circuit board with hot air gun, use soldering iron to apply a thin layer of solder on it. After soldering is completed, use alcohol to remove the residual flux on the circuit board. Precautions for hot air gun blow soldering new circuit board, blow soldering time is appropriate, and the solder joints are round and smooth.

Method of hot air gun blow soldering new circuit board

I. Operation steps of hot air gun blow soldering new circuit board

(1) Use 0.6 mm rosin small solder on the component pad. The electric soldering iron should be placed on the soldering iron rack. It is forbidden to place it randomly. Use the soldering iron to apply a thin layer of solder on it. After soldering is completed, use alcohol to remove the residual flux on the circuit board.

(2) Clamp the two ends of the component with tweezers, preheat the rosin with a hot air gun, and stick the parts with melted rosin, and then place them on the soldering pad of the circuit board.

(3) Place the component.

(4) Blow solder with a hot air gun to melt the solder in the soldering pad.

(5) After soldering, remove the hot air gun in time.

(6) Use a cotton swab dipped in board washing water to wipe off the excess rosin.

2. Precautions for hot air gun soldering new circuit boards

1) Component placement must meet the requirements:

① Place the marked side facing up.

② Confirm the direction of components with polarity.

③ Align the first pin of the integrated circuit with the first pin of the circuit board.

2) The soldering time is appropriate. Note that the time should be appropriately extended in places with heat dissipation design to avoid false soldering.

3) The displacement should be controlled. After the solder solidifies, do not adjust the chip components. Before solidification, you can make a slight position adjustment to remove the oxide on the surface of the pin, thereby achieving the purpose of reducing false soldering.

4) Solder point requirements: The solder point is round and smooth, without abnormal phenomena such as bridging of the tip and connecting adjacent pins.

5) The tweezers cannot be loosened before small and micro components are soldered firmly, so as to avoid hot air blowing away the parts or causing abnormal phenomena such as displacement and cold soldering.

6) It is generally not recommended to use a hot air gun to solder traditional jack lead components.

7) When soldering SMD components, be sure to preheat them to prevent them from being damaged by sudden thermal expansion. The preheating temperature of SMD resistors, SMD capacitors, SMD diodes, and SMD transistors is generally around 100°C, and the preheating time is 1-2 min.

8) When soldering, it is forbidden to keep the component pins and the surface of the copper foil of the printed circuit board unclean to avoid cold soldering.

9) Improper welding temperature can easily cause faults such as pin solder short circuit, cold soldering, and printed circuit copper foil detaching from the printed board.

10) When soldering, it is forbidden to have too small a contact surface between the component pins, the copper foil of the printed circuit board, and the soldering iron tip to prevent heating too slowly and cold soldering due to insufficient temperature.

11) When soldering, it is forbidden to use improper soldering to avoid cold soldering.

Skills and techniques 1: Some taboos when using electric soldering irons 1. Newly purchased electric soldering irons are forbidden to absorb tin. Tinning is also called tinning. Clean the soldering agent to prevent the carbonized flux from affecting the normal operation of the circuit.

2. When soldering electronic components, it is forbidden to use very high temperature solder wire.

3. After the soldering operation, it is forbidden to wash your hands, because lead is a heavy metal that is harmful to the human body.

During the soldering operation, it is forbidden to keep your nose too close to the soldering iron tip.

4. It is forbidden to be careless during soldering to avoid scalding people, power cords and clothes.

5. It is forbidden to move the soldering iron tip back and forth on the soldering point.

6. It is forbidden to brush tin on the soldering foot with the soldering iron tip.

Skills and techniques 2:

Small experience in using hot air guns

a. The wind force and temperature of the hot air gun can be adjusted by placing a paper strip 10 cm in front of the hot air gun nozzle. The wind force of the hot air gun can be judged by the degree of swing of the paper strip, and the temperature of the hot air gun can be judged by the degree of heat of the paper strip.

b. Although the power switch of the hot air gun has just been turned off, the hot air gun will continue to spray outward. Therefore, generally, unplug the power plug of the hot air gun after the air jet ends.

c. If you have a hot air gun, do you not need an electric soldering iron? Generally, hot air guns are used to disassemble and solder components, while electric soldering irons can be used to solder/re-solder components and clean residual tin. Therefore, in actual work, hot air guns must be used in conjunction with electric soldering irons.

d. When disassembling BCA chips, it is best to choose and use a hot air gun with a CNC constant temperature function so that the temperature can be controlled, and the air nozzle can be removed for direct blow soldering.

e. Tips for using a hot air gun: Hold the component with tweezers or other clamps in one hand, and use the hot air gun with the other hand to blow back and forth on all the pins of the SMD component. When the pin solder melts, the SMD component can be lifted. After removing the SMD component, clean the pad with a soldering iron.

Finally, I want to say that when using it for PCB boards, we'd better use a constant temperature hot air gun to avoid the uncontrollable temperature of some bad hot air guns that may cause the PCB to burn. I recommend you to use SNUOK's constant temperature hot air gun. The temperature output is stable and has better operability.